| Product Overview |

| |

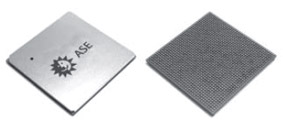

HFC BGA (High Performance FCBGA), a thermally enhanced FCBGA, is the composite package of FCBGA with heatspreader made of Cu, Al, or AlSiC. The heatspreader is used to extend the heat conduction area by connecting itself to the rear side of the silicon chip.

This method desensitizes the performance deviation out of the chip size, lowers the thermal resistance of junction-to-case (θJC) and enables the external heat sink or fan to work more effectively. HFCBGA can produce 6~8 watts of power dissipation under natural convection. |

|

| Application |

| |

Computer

Graphics/chipsets for PC

Server and High-end application

Microprocessor for PC & Server

Telecommunications

Network products (eg. LAN)

Switching

Transmission

Cellular Base Stations |

|

| Features |

| |

| Substrate |

4 layer laminate, 4~12 layer build-up, ceramic, and PTFE substrates are available |

| Thermal Lids |

Heat spreaders made of Cu with Ni plating, Aluminum, Ceramic, AlSiC |

| Passive Component |

Passive component attaching. It can be placed on the top or bottom side of the package |

| Ceramic BGA |

High Pb solder ball with eutectic solder paste improves board level reliability performance of ceramic packages |

|

|

| Reliability |

| |

| Package Level |

| Test Item |

Reference Standard |

Condition/Duration |

| MSL |

JEDEC 22-A113 |

Level 4, 30°C/60% RH, 96 hrs |

| TCT |

JEDEC 22-A104-B |

-65°C to 150°C, 500, 1000 cycles |

| THT |

JEDEC 22-A101 |

85°C/85% RH, 500/1000hrs |

| HAST |

JEDEC 22-A118 |

130°C/85% RH, 33.5 psi 50/100hrs |

| HTST |

JEDEC 22-A103-B |

150°C, 500/1000 hrs |

| PCT |

JEDEC 22-A102 |

121°C/100%RH , 15 psig, 96/168hrs |

|

| |

| Board Level (Contact ASE for further details.) |

|